Custom Control Systems for bi-fuel Powertrain Development

The Challenge

Our customer needed a flexible system to evaluate a range of engine actuators, sensors, and controls to guide their future engine offerings. After the evaluation, they wanted an adaptable control system to allow efficient multi-variable engine dyno testing.

Result

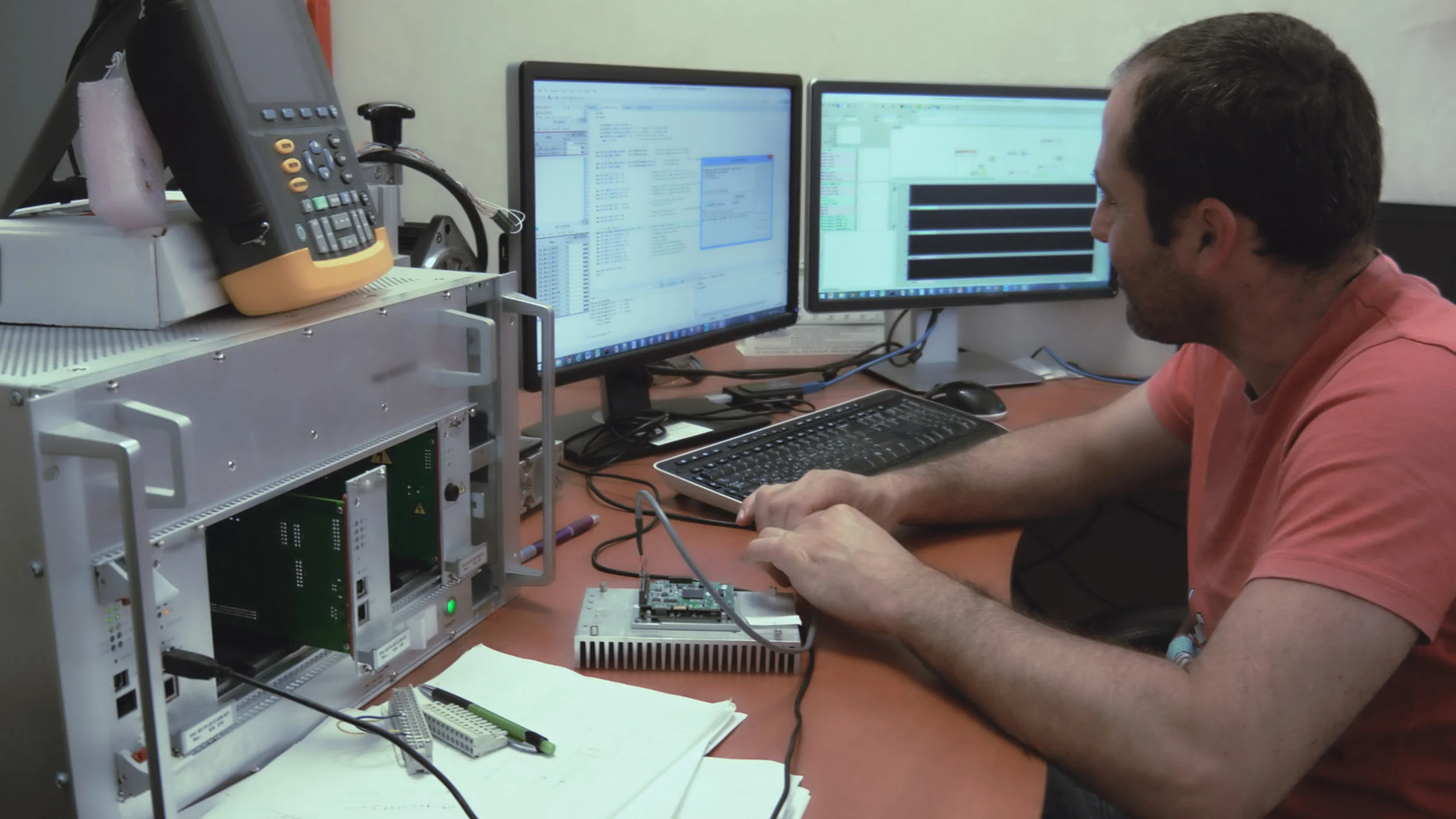

Pilot engineered a dSPACE SCALEXIO-based HIL system to allow the study and evaluation of a wide range of engine components. Building from this, we implemented a dSPACE MicroAutoBox-based RCP control system for engine dyno testing.

When we were approached to engineer these two systems, we knew we’d have to combine flexibility, adaptability, and solid engineering to implement capable, reusable systems. With a wide range of possible actuators (port injectors, direct injectors, dual fuel injectors, high and low pressure valves, throttle bodies galore) and an unrestricted set of sensors (lambda, pressure, temperature, position, …) only the combination of dSPACE SCALEXIO and MicroAutoBox would allow the control range needed. Fortunately, our expertise and systems approach, combined with dSPACE’s hardware enabled the systems to be designed and implemented inside a year and to fire up and run first time out of the box.